Wall thickness is the distance between the outside diameter and the inside diameter of the pipe measured in thousandths of an inch. The inside diameter (ID) is the longest distance across the inside dimensions of a tube or pipe. You can shop the Pro-Tools website for benders and dies that bend up to 2-1/2" OD if you need to bend tube or pipe larger than 2-1/2" OD, please give our expert technical sales team a call at +1 (813) 986-9000. The outside diameter (OD) is the distance across the extreme outside dimensions of a tube or pipe. Pro-Tools sells a full line of Bend-Tech software to fit the needs of any metal fabricator. The software then uses the stretch/compression data to properly calculate the amount of material in each bend as well as the proper bend locations. This value is obtained using a calibration test, by bending a test piece of material and measuring the resulting legs. When using Bend-Tech Software, this value is used to specify how much stretching and compressing will occur during each bend. Because of this stretching, you will find that the CLR of a bent piece of material is slightly larger than the CLR listed on the die.Ĭalibrated Center-line Radius (Calibrated CLR):

Material will spring or stretch open after it is bent think of coiling a wire around a pencil – release the wire and it will fall off the pencil. Pro-Tools dies have the CLR inscribed on it.

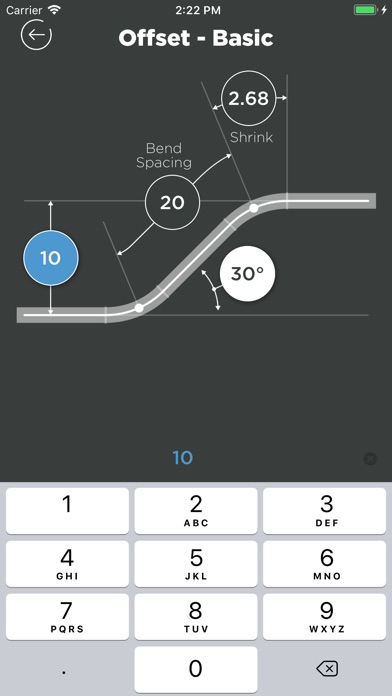

This value is the radius you obtain when bending with the die. All of Pro-Tools tube and pipe benders are capable of bending up to a 7" CLR the tightest CLR that you can bend is 2" (depending on your material), using the Pro-Tools 105 Standard Duty or Heavy Duty Benders.Īchieved Center-line Radius (Achieved CLR): When choosing a die, factors that will affect the CLR you choose include the material type and grade to be bent, wall thickness, the OD, the application or design of the end product, and overall appearance required. If you’re having trouble translating that last sentence into English, check out the picture above. Using the image below, you can see how the radius of a bend has a significant impact on the resulting part. CLR is the distance from the center of curvature to the centerline (axis) of the pipe. When referring to the radius of a die, we are referring to the center-line radius (CLR) that results from bending. USE THIS DIAGRAM AS A REFERENCE WHILE YOU LEARN TUBE AND PIPE BENDING BASICS If you need additional assistance, don't hesitate to give Pro-Tools a call and our team will be happy to help you. To get started bending tube or pipe in your shop, Pro-Tools has put together these basic metal fabrication terms to make beginning your first bending experience as easy as possible.

0 kommentar(er)

0 kommentar(er)